ESG Economist - Is carbon capture economically viable?

To achieve the global goal of net-zero emissions by 2050 and limit global warming to below 2°C (preferably 1.5°C) above pre-industrial levels, we need a mix of solutions. These include reducing CO₂ emissions, capturing emissions directly from combustion, and removing CO₂ from the atmosphere. While much focus has been on reducing emissions (like using renewable energy or sustainable fuels), carbon capture and storage (CCS) is gaining attention, especially for hard-to-abate sectors like heavy industry and transport (shipping).

Currently, CCS is mostly used on a small scale. In 2023, only 0.1% of global CO₂ emissions were captured, and even with future expansion, it will make up a relatively small share of reductions by 2030. However, CCS is essential to complement other solutions, particularly in sectors where emissions are difficult to eliminate. While we have extensively written about CCS on carbon capture (see here) CO2 transport (see here) CO2 storage (see here) and the possibilities for using CO2 (see here). This note will focus on the cost to capture CO2, the costs to avoid CO2 and compare them with the ETS price. But we start with explaining what carbon capturing (the CC of CCS) exactly is.

Carbon Capture and Storage (CCS) is a critical technology for achieving net-zero emissions…

…particularly for sectors where emissions are hard to eliminate

While its current adoption remains limited due to high costs…

…rising carbon prices and advancements in carbon capture technology will likely make it a more viable solution by 2030

Ongoing innovation is essential to reduce costs and increase the scalability of this technology for a sustainable future

Carbon capturing (CC) explained

Before we start digging into the costs of carbon capture, it is noteworthy explaining what this technology is. Carbon capture involves removing CO₂ from the emissions of fossil fuel combustion before it enters the atmosphere. This carbon captured is then transported and stored. There are three main carbon capture technologies.

Post-Combustion Capture

CO₂ is captured after fossil fuels are burned, from the exhaust gases (flue gases).

Commonly used to retrofit existing power plants.

Techniques include chemical solvents, physical solvents, adsorption (using solid materials), and membranes.

Pre-Combustion Capture

CO₂ is removed before combustion, typically by converting fossil fuels into a cleaner gas (syngas).

Used in industrial applications or integrated gasification systems.

Oxy-Fuel Combustion

Fossil fuels are burned in pure oxygen, creating a high-purity CO₂ stream that is easier to capture.

Often used in new infrastructure projects.

How to separate CO2 from gases

Separating CO₂ from gases (like those emitted by power plants or factories) is key to carbon capture. There are different techniques to achieve this, and each has its own advantages and challenges. The first technique is absorption using liquids (solvents). The CO₂ is absorbed into a liquid solvent (like a sponge soaking up water). The solvent is then heated to release the CO₂, leaving it ready for storage or use. Afterwards the solvent is reused in the process. There are chemical solvents and physical solvents. The downside to this technique that it is an energy-intensive process, especially for chemical solvents.

The second technique is adsorption using solids (sorbents). Instead of liquids, this technique uses solid materials to "grab" CO₂ on their surface. The CO₂ sticks to the surface of the solid material (like a magnet). The CO₂ is later released by changing temperature or pressure. This technique uses less energy to regenerate compared to solvents, but it still being developed, especially for large-scale use.

The third technique is membrane separation. Think of a filter that lets CO₂ pass through while blocking other gases. In this technique there is no need for chemicals, making it cleaner and simpler. Moreover, it can reduce energy use compared to other methods. But the membranes are not yet efficient enough for large-scale use.

The fourth technique is cryogenic carbon which is freezing CO₂. This method cools (-100°C to -135°C ) gases so much that CO₂ turns into a solid (frost) and can be separated. The frozen CO₂ is collected and converted back into a gas or liquid for storage. This technique can also remove water and other pollutants. However, it uses a lot of energy.

Last but not least there is a newer technique that uses a special solvent (potassium carbonate) to absorb CO₂. This process requires less energy compared to traditional solvents. Moreover, is more efficient and doesn’t degrade easily like amines.

Costs of capture and avoidance

Now we have explained what CCS is and what techniques are used we dive into the cost to capture CO2 and the cost of avoidance. For this we use Bloomberg NEF CCS models for industry, power and high concentration (ethanol, ammonia, natural gas processing). High concentration means that the flue gas has a high concentration of CO2 of 93.5% of higher. Industry for example produce flue gas with a CO₂ concentration of 13-23% so it needs to be processed further to purify the CO2 for transport and storage.

Although the cost of capture and the cost of avoidance look similar there is an important difference to make. The cost of capture describes how much it costs to capture one ton of CO₂. The cost of avoidance describes how much it costs to avoid one ton of CO₂ entering the atmosphere. It factors in the emissions that result from producing the energy required to run the capture plant.

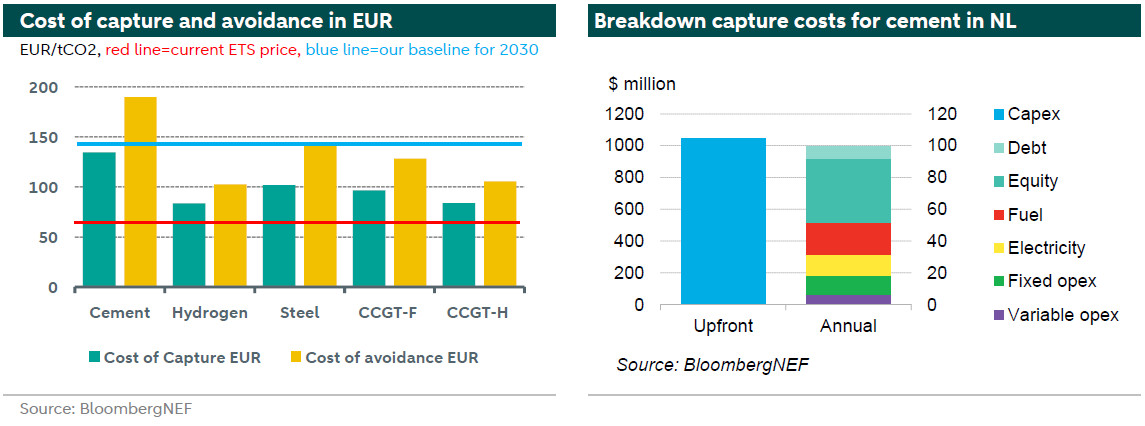

The graph below on the left shows the cost of capture and cost of avoidance for the industries cement, hydrogen and steel and for the Combined Cycle Gas Turbine (or CCGT) in the power sector. CCGT combines two energy generation processes – gas turbines and steam turbines- to produce electricity. CCGT can be classified as F- or H-class, with the H-class representing the latest generation of gas turbines. CCGT-H is a hydrogen-fuelled combined cycle gas turbine and CCGT-F is a fossil fuel-powered CCGT. The CCGT-Hs produce less CO2 than CCGT-Fs. These costs are calculated assuming natural gas as fuel source, with a construction year of 2025, construction time 3 years and operating life of 30 years. The costs are projected to be similar for the Netherlands and Germany.

As the graph above shows it is not attractive for the power sector to make the investment in CCS as the cost of capture and the cost of avoidance lie above the current ETS price. That is also the case for the cement, hydrogen and steel industry. This means that buying ETS allowances is currently cheaper for these companies than to invest in carbon capture technology. Towards 2030 investing in carbon capture technologies will become a more attractive solution as our baseline scenario sees ETS prices rising to €145/tCO2 by 2030 (the blue line in the left chart above, see more here).

The graph above on the right shows the estimation by Bloomberg NEF that is required to build a CCS system for a 1.3 Mt/yr cement plant in the Netherlands. The capital expenditure (capex) is the largest component. So, the initial investment for such plant is USD 1,048.5 million and then the annual costs still need to be added. The fixed operational expenses (opex) are also substantial at USD 11.5 million annual. Most of capex and opex are fixed.

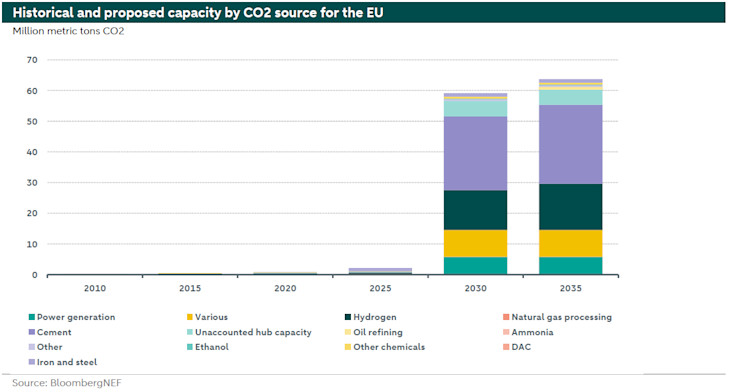

The graph below shows the historical and proposed capacity by CO2 source for the EU. It shows that in 2025 there are only limited projects for carbon capture. By 2030 carbon capture could become more used in the industries cement and hydrogen and power generation. But the costs for these technologies need to decrease or the ETS price needs to increase.

Conclusion

Carbon Capture and Storage (CCS) is a critical technology for achieving net-zero emissions, particularly for sectors where emissions are hard to eliminate. While its current adoption (shown by the low number of projects) remains limited due to high costs, rising carbon prices and advancements in CCS technology will likely make it a more viable solution by 2030 due to rising ETS prices. From post-combustion to cryogenic methods, ongoing innovation is essential to reduce costs and increase the scalability of CCS for a sustainable future.