Latest news

more ABN AMRO newsParties sign MoU to accelerate the rollout of sovereign, Pan-European payment solutions

Article tags:

- Products and services

-

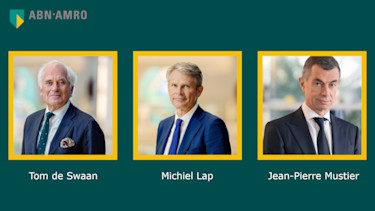

ABN AMRO appoints Michiel Lap as Chair; nominates Jean‑Pierre Mustier to Supervisory Board

Article tags:

- About us

-

ABN AMRO helps homeowners make sustainability improvements without higher monthly costs

Article tags:

- Sustainability

- Housing Market

-

How we make a difference

Equal opportunities

Through our services, our employership, our sponsorship and the ABN AMRO Foundation, we aim to help contribute to a society in which everyone participates.